-

Phone

86-533-6412127

-

Address

No. 1997, Sichou Road, Zhoucun District, Zibo, Shandong, China

-

E-mail

Welding Flux Sj501 for Submerged Arc Welding

China Welding Flux Sj501 for Submerged Arc Welding, Find details about China Welding Flux, Submerged Flux from Welding Flux Sj501 for Submerged Arc Welding - Zibo Qilu Welding Industry Co., Ltd.

Description

- Model NO.: welding flux SJ101, SJ301, SJ501

- pH: Alkaline

- Melting Point: >600℃

- Function: Protect Weld Metal

- Manufacturing Method: Non-melting

- Quality System: ISO9001: 2008

- Sample: Can Offered

- Content: Fluorine, Alkali

- Current: AC or DC

- Trademark: MIGHTY BRAND

- Specification: grain: 8-40 meshes (2.5-0.38mm)

- HS Code: 3801900000

- state: Solid

- Type: Inorganic

- Chemical Composition: MnO=15%-30%

- Application: Submerged-arc Welding

- Model No.: Welding Flux Sj501

- Certification: ABS, CCS, Lr, Dnv

- Performance: Easy to Slag, Smooth Welding Bead

- Color: Grey

- Grain Size: 2.0-0.45mm (10-40 Mesh)

- Transport Package: 25 Kg/Kraft Paper Bag, 40 Bags/Pallet

- Origin: Qingdao, Shandong, China

GB/T5293-1999 F5AZ-H08A F5A2H08MnA

AWS-A5.17 F7AZ-EL12 F7A2-EM12K NB/T47018-2011

Welding flux is needed while submerged arc wire welding.

There are SJ101, SJ301 and SJ501 in our warehouse.

Description:

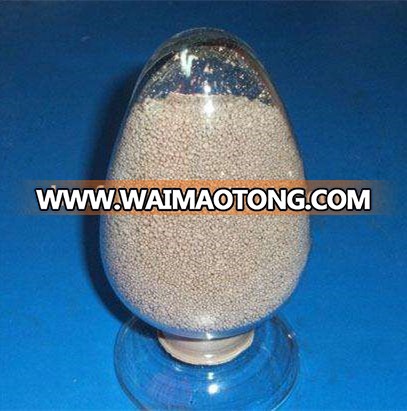

Agglomerated flux SJ501 is a kind of acid aluminum-titanium type sintered

flux, the basicity index is about 0.8. It is shaped as black, round grains and its

grain size is 2.0-0.28mm (10-60Mesh). It can be used with either AC or DC.

The welding wire is connected to the positive electrode when used with DC. It

has stable combustion, good slag detachability and good appearance of weld.

It has a thick skin to a small quality of rust and high temperature oxidation

film on account of strong the capability of resist pore.

As a peculiar production technique is adopted, the flux possesses better

moisture resistance and good strength of grains, which may satisfy the

requirements for regular transportation, storage and recycling use in welding.

The flux has less specific gravity when it is bulk packed. And it is consumed

less during the welding.

Application:

With suitable welding wires(H08MnA. H08MnMoA. H10Mn2), it can welding

common structural steel, boiler steel, pipeline steel, etc. The flux can be used

for multiple fast welding, and can be suitable for single-sided welding,

especially suitable for pressure vessel, such as oil and gas pipes, tanks and

cylinders of automatic submerged arc welding.

Cautions:

1.The oil contamination, moisture, iron rust and other foreign substances must

be removed from the welding joint.

2. It is better to weld under direct current.

3. Welding flux must be baked under 300-350°C for more than 2 hours before

usage.

Chemical Compositions(%):

| Al2O3+MnO | CaO+MgO | SiO2+TiO2 | CaF2 | S | P |

| 25~30 | 25~30 | 15~20 | 15~20 | ≤0.03 | ≤0.03 |

(Mechanical Performance of the Deposited Metal):

| Wires | Standard Models | бs(Mpa) | бb(Mpa) | δ5 | Akv(J) |

| HO8A | F4A2-HO8A | ≥330 | ≥420 | ≥22% | ≥27 |

| HO8MnA | F5A2-HO8MnA | ≥400 | ≥500 | ≥22% | ≥27 |

| Fit | GB/T5293-1999 | F4A2-H08A | F5A2-H08MnA |

| Equivalent to | AWS-A5·17 | F6A2-EL12 | F7A3-EM12 |

Mechanical Property:(according to GB5293-1999 F4A1-H08A)

| Test Item | Tensile Strength (MPa) |

Yield Strength (MPa) |

Elongation (%) |

Impact Absorption Rate (J) |

| -40οC | ||||

| Guaranteed Value | 410~550 | ≥330 | ≥22.0 | ≥27 |

Notes for welding:

1. Redry the flux for 2 hours at 300-350º C prior to be used.

2. Some rust, oil, moisture and other impurities must be cleared away from

the area to be welded.

Our Service:

1. Professional service for products

2. Much more competitive price

3. Honest and excellent supplier

4. Delivery time is shorter than others.

5. We believe the good quality is the basis for cooperation.

6. We could provide the samples for test to you.

7. Our company policy is Quality First, and to establish Long Time business,

not just one time

How to contact us?

Mr. Jacky-MIGHTY QINGDAO METAL MATERIALS CO., LTD.

Tel: +86-0532-66010291

Add: Room 705, Building A, Heda Office Building, NO. 175, Tailiu

Road, Shibei Strict, Qingdao, China

Related Products

-

Agglomerated Welding Flux Sj101, Esab Ok 10.70 Flux Powder (SAW)

-

LPG cylinder Flux SJ501 F7A0-EM12K/Submerged Arc welding flux/High Speed welding flux

-

REFULGENCE BRASS BRAZING FLUX, BRASS WELDING POWDER, CJ301 BRASS WELDING FLUX

-

China Supplier with High Quality Welding Flux Sj101 Submerged Arc Welding